Rosin Vs Resin: Whats The Difference? | Live Resin

Rosin Vs Resin

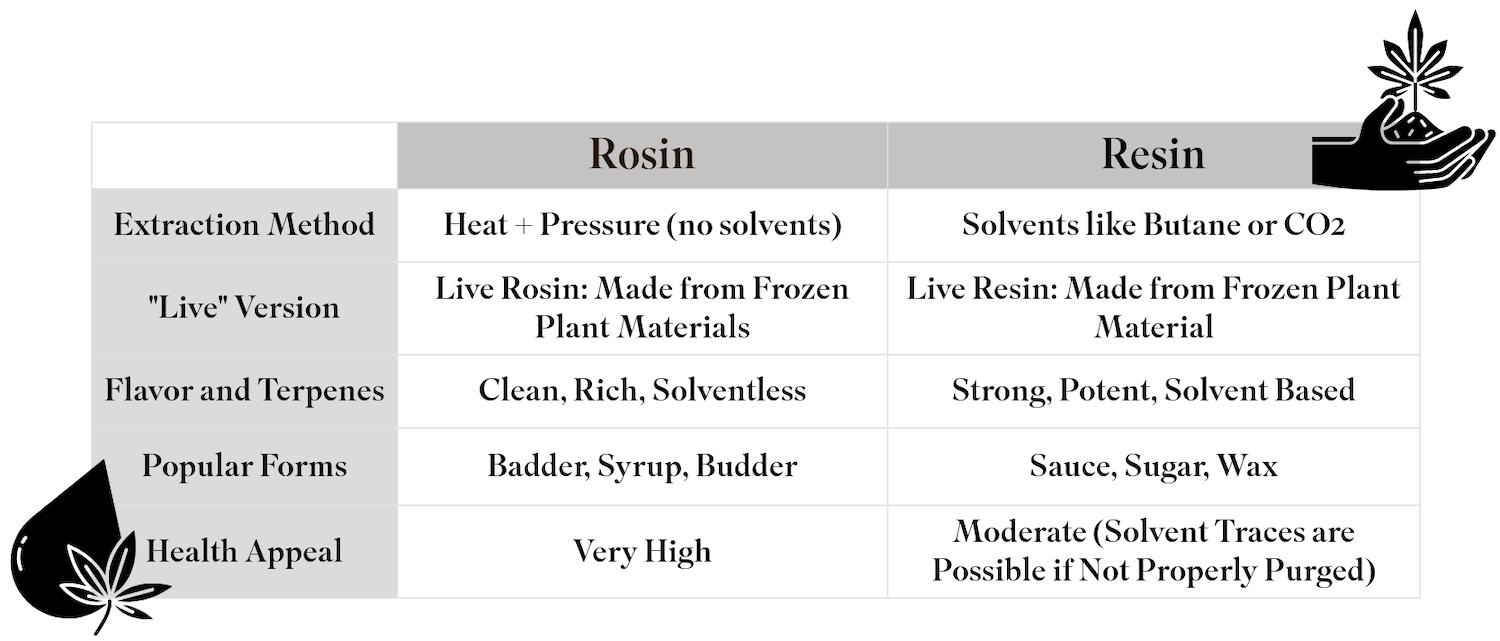

Rosin and Resin have quite a few differences, and no, we are not just talking about the letter “o” and the letter “e”. Although both of these concentrates are widely used and relatively easy to find within the dabbing community, some might be confused as to which is which and why each extract is labeled differently.

Here is a quick little comparisson chart but well also give you guys the general breakdown.

Rosin:

Rosin is made without any solvents, like butane, propane, co2 or ethanol so people tend to gravitate towards it because it seems a bit “healthier”. At the end of the day, no one really wants to inhale propane.

The texture and look of Rosin can vary, once extracted it can look a bit like syrup or it can have a more creamy sort of texture like budder or even crumble, depending on the material and how it's been cured. Its color can vary between green, yellow, amber, brown, or off white.

Rosin is typically made from cured and dried plant matter or hash, however it can also be made with frozen plant materials giving it the name “Live Rosin”.

The difference between Live Rosin and Cured Rosin, is that Live Rosin most likely has a higher terpene content than Rosin made of cured flower does.

This is because the cannabis plant is flash frozen before the extraction process begins. Flash freezing cannabis conserves the terpene content of the plant, which would otherwise degrade over time or with intense heat.

The beauty of Rosin and the reason why this type of concentrate is even called “Rosin”, is the way it's made, with a Press.

A Rosin Press uses both heat and pressure to squeeze all of the essential compounds out of the plant material. The oil is then harvested and can be used for a number of different things including dabbing!

Rosin is appreciated for being clean, flavorful, and free of residual solvents. The cleanliness of rosin is what makes it appealing to health-conscious dabbers.

Resin:

The word “resin" is used interchangeably to classify all types of concentrates that are extracted using solvents, or it can be used on its own as a name of a concentrate. It's sometimes hard to understand, especially for beginners, since some people use it differently.

In our book Resin is just Resin.

Just like Rosin - Resin can be labeled as Live Resin or Cured Resin, the difference is whether the plant is cured or frozen before its extraction process. Resin is typically made of flash frozen cannabis, giving it the name “Live Resin”, while Cured Resin is usually made of cured plant materials.

Once the frozen plant is ready for extraction, it is ground up into smaller pieces and a solvent is added. Resin is usually extracted using solvents like butane or co2.

The solvent works its magic to extract all the necessary and "desirable" parts of the plant, the rest of the plant material is discarded after. Then the solvent is evaporated from the leftover oil and solvent mixture, leaving behind a thick amber concentrate that is ready to dab!

The reason why people prefer Resin, is because of the “Live” aspect of its extraction process. You usually see live resin widely available offering a terpene rich, super smooth dab with enhanced effects from the additional compounds!

What is Cured Rosin/Post Processing?

“Cured rosin” is another term also thrown around often, you would think that it's because this type of extract is made of cured plant materials. However, this is not ALWAYS the case, sometimes “cured” refers to the curing process that actually takes place after the extraction is already done.

There are two ways to cure rosin, either cold curing or heat curing. Both curing methods require the rosin to be sealed inside the jar. For cold curing you would want to leave the rosin in cooler temps around 40-60 degrees for days and even weeks until you achieve the aroma and texture you are looking for. For heat curing, you would leave the jar of rosin in warmer temps around 90-225 degrees for hours, sometimes days, or sometimes weeks.

Cold curing will help you achieve textures that are similar to badder and improve the shelf life of your rosin. Heat curing will help you achieve textures that are similar to sauce and will improve the stability of your extract when it reaches room temperature!

Recent Posts

-

12 Best Cannabis Strains for Pain

Why Do People Search For Cannabis Strains for Pain Relief Cannabis has been used as a holistic appro …24th Feb 2026 -

Every Dabber Needs a Hot Knife

You're all geared up, you have your dab loaded on your dab tool, your banger is piping hot ready for …19th Feb 2026 -

Terpenes Explained: A Complete Guide for Dabbing & Flavor

Terpenes are an important part of the equation when it comes to the type of high you'll experience. …13th Feb 2026