How To Make Dabs? | DIY Dabs | Rosin, Ice Hash, Solvents

There are many different ways to make your own dabs, but first lets start with the more at home diy methods instead of the extraction methods using flammable solvents.

Rosin Press:

Rosin presses use heat and pressure to extract “dabs” out of hash or frozen plant / cured plant material. This is a pretty straightforward and simple way to make your own dabs at home. However, rosin presses can be rather pricey and take up a lot of space. As long as these two factors are not an issue you should be off to the races rather quickly!

All you need is your plant materials, two pieces of parchment paper and your press.

- Place your flower in between the two pieces of parchment paper.

- Then place your flower and wax paper in between the two plates on the rosin press.

- With a combination of warm temps and pressurized force, your “rosin” will start to seep out of the crushed plant.

- You can collect this oil to start dabbing right away!

- You can also cure your Rosin to achieve a different texture and make it more shelf stable!

Check out this blog that explains cold curing and hot curing rosin.

Special Mention:

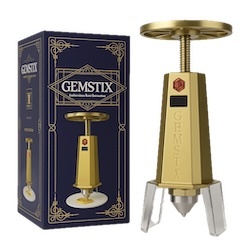

This Portable Rosin Press, known as the GEMSTIX, delivers the ideal combination of adjustable heat and pressure depending on the materials being extracted. This extractor is the first of its type, combining microfiltration capabilities and handheld portability.

The GEMSTIX Handheld Rosin Press weighs less than two pounds, making it extremely easy to maneuver and use with minimal effort. The temperature may be changed from 130 degrees to 260 degrees, and it can extract 10 grams of material in just a few minutes!

Ice Hash Extraction:

Ice Hash extraction only requires a collection of mesh bags, ice water, and your plant materials. This extraction method is fairly easy and straightforward for the at home cannabis diy-er. However, filtering your plant through mesh bags might result in some waste of the good stuff and the extraction process itself can take a while.

- Start by placing your plant material into micron mesh bags (also called wash bags or work bags), then submerge them in ice-cold water inside a large bucket.

- Gently stir and agitate the mixture. The cold temperatures make the trichomes (glands) break off easily, causing them to sink to the bottom of the bag.

- Continue stirring for 10–20 minutes, alternating between gentle and more vigorous motion. This helps release as many trichomes as possible without breaking up plant matter.

- Once you've finished mixing, pour the mixture through a series of bubble bags (micron filter bags stacked by size, from largest to smallest microns). These bags separate trichomes by size.

- Each layer will catch different grades of hash. The smallest bags usually collect the highest quality hash.

- Carefully collect the hash from each bag, being gentle to avoid contaminating it with water or plant matter.

- Let the wet hash dry completely. You can use a drying screen, freeze dryer, or air-dry in a cool, dark, low humidity space.

- Once dried, the hash can be pressed into hash, dabbed or smoked as is, or further pressed into rosin.

Ethanol or Isopropyl Solvent Extraction

Solvent extraction produces some of the best results when it comes to potency and also the highest yield. You can use either ethanol or iso alcohol for this type of extraction process however it is recommended to go with ethanol instead. This is because ethanol is safe for humans, while iso is not. The solvent is always completely dissolved from the oils at the end of the extraction process. In spite of that, your dabs CAN sometimes contain residual solvents, it's better off if the solvent is non toxic in case it is consumed, for health and safety purposes.

Please Note that alcohol is a very flammable substance and this process should be completed in a well ventilated area with absolutely no open flames. The fumes that evaporate off of alcohol are ALSO very flammable. Do not use a flame stove top, torch, or lighter when completing this extraction process. Have a fire extinguisher handy in case of an emergency!

- For this extraction process you will want to start off by breaking down your flower into pieces, removing the stems. Try to complete this process by hand instead of using a grinder, the larger pieces will be easier to strain once the extraction is completed.

- Place your plant materials into a glass jar or dish filled with ethanol alcohol (again isopropyl can be used but it's not recommended). Make sure all your materials are completely submerged.

- Stir the mixture slowly for 10-15 minutes so that the alcohol is fully soaked into your flower.

- Then use a strainer to remove your plant materials from the alcohol mixture. You can pour the mixture over a coffee filter into a new glass container. By this point you should be left with a greenish looking liquid.

Now you need to remove the alcohol from the concentrates, you can do this in a few different ways.

- Air Vaporization - You can leave the mixture out for a few days to fully vaporize the alcohol from your dabs. Make sure this is done in a well ventilated area, you can leave a fan to blow over it to help the vaporization process move along faster. DO NOT USE A HEATER.

- Water Bath - Fill a large saucepan with water, place the glass dish or jar inside the water. Do not submerge the glass dish or jar. Make sure you do not have a top on the jar or dish. Set your electric stove top (make sure there is no open flame) to low and allow the water to heat the jar indirectly. After a few hours the alcohol should be fully evaporated!

- Rice Cooker - Pour the alcohol and oil mixture into a rice cooker. Set the rice cooker on low for a few hours until the alcohol has fully evaporated.

Once the alcohol is fully evaporated, you should be left with a green - yellow concentrate. You can manipulate and further process this extract to get the consistency you desire!

If you are unsure if the alcohol has fully dissolved from your extract you can pick up a small portion of it with a dab tool. Take it to an open flame to see if it catches fire aggressively or if it sparks up. If this happens you need to let the alcohol evaporate longer.

Butane or Propane Solvent Extraction:

Butane and Propane have been used for years to make dabs, however this extraction method is best left to the pros because of the potential dangers involved. Butane and Propane can explode if they are handled incorrectly. If you would like to make your own dabs at home we suggest going with any of the three methods above. If you find yourself around some pros with lab equipment or you are just curious on how it's done, you can read on below!

To complete this extraction method you will need lab grade equipment including a closed loop extractor including a recovery pump, a vacuum pump and oven, and all of the necessary safety equipment. (Safety glasses, gloves, fire proof clothing, ventilation, and gas detectors)

- First you will need to load your plant materials into the material column located on the closed loop extractor, this column is usually made of steel or glass.

- Next, inject your ultra-pure butane, propane, or a blend of both into the system. The solvent is chilled and pressurized, then passed through the material column, dissolving cannabinoids and terpenes from the plant material.

- After the extraction is complete, the butane/oil solution flows into the collection chamber. Here, the solution is filtered through micron screens to remove plant particulates, leaving behind a mixture of solvent and extract.

- Using gentle heat and vacuum pressure, the system begins to evaporate and separate the butane or propane from the extract. The vaporized solvent is then pulled into the recovery tank, where it's cooled, condensed, and stored for reuse.

- What remains in the collection chamber is your raw extract - but it still contains trace amounts of solvent. To ensure it's safe for consumption, it must be purged again using a vacuum oven.

- The extract is transferred to parchment paper or trays and placed into a vacuum oven connected to a vacuum pump. At low temperatures and under vacuum pressure, the oven gently heats the concentrate and removes residual solvent over 24 to 72 hours, depending on the consistency you’re aiming for.

Recent Posts

-

12 Best Cannabis Strains for Pain

Why Do People Search For Cannabis Strains for Pain Relief Cannabis has been used as a holistic appro …24th Feb 2026 -

Every Dabber Needs a Hot Knife

You're all geared up, you have your dab loaded on your dab tool, your banger is piping hot ready for …19th Feb 2026 -

Terpenes Explained: A Complete Guide for Dabbing & Flavor

Terpenes are an important part of the equation when it comes to the type of high you'll experience. …13th Feb 2026